Business

The Secret to Long-Lasting Custom Prints – Why DTF Printing Stands Out

Here’s why DTF printing could be a gamechanger for your business.

Custom printing is a booming business in the apparel industry. This can provide unlimited design options and customisations to suit various likings and occasions. However, colour fading and lack of durability are common issues in fabric printing. Customers want prints to stay intact and vibrant even after frequent washing and constant wear. This is where DTF printing stands out, offering longevity while keeping the prints vibrant.

What Affects Print Longevity?

Print longevity depends largely on the process of printing the design. The following are some common factors impacting print longevity:

Fabric Type

Cotton and cotton blends, linen, and polyester last longer due to their natural ability to absorb colours. However, fabrics like silk, wool and nylon are more prone to crack and fading.

Ink Quality

Cheaper inks that are water-based are less durable and fade over time. Solvent-based and pigment sublimation are good inks that are water-resistant and merge well with fabrics.

Printing Technique

Techniques that require longer drying times can affect durable prints. For example, screen printing is more prone to fading, peeling and cracking over time. This is due to the exposure of sunlight to dry the ink, which causes damage.

Heat Application

Heating methods like pressing, curing, steaming, and sun drying can affect the longevity of the prints. Most long-lasting apparel is created using methods that require less time to dry the inks.

How DTF Printing Ensures Durable Results

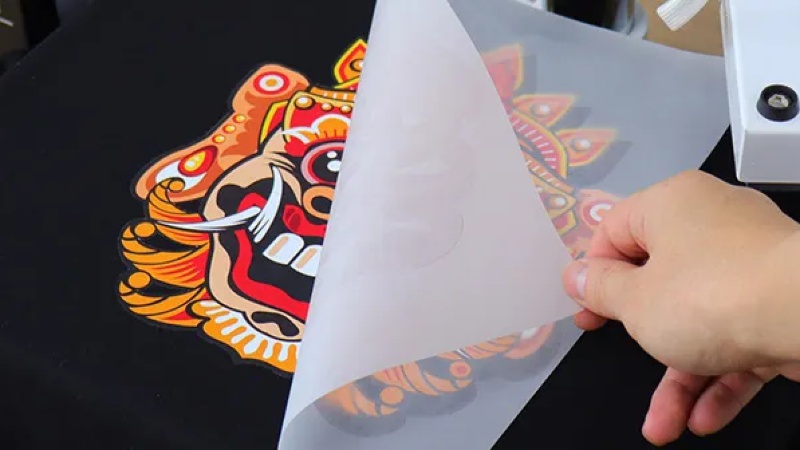

Unlike other printing methods, DTF printing offers lasting results due to its unique ink printing process. High-quality DTF printers use PET film to transfer the designs to a white surface. A copy of the design is pasted on this film using adhesive powder. The heat is transferred to this powder, and it merges with the design, creating a strong bond between print and fabric. This process results in fade-resistant printing that is resistant to wear and tear.

The Science Behind DTF Ink & Adhesion

PET film, when used with adhesive powder, enhances the chances of ink absorbency. The water-based ink used in this method produces durable prints. This helps in providing vibrant prints without merging the colours together due to heat curing. It offers excellent adhesion with cotton, cotton blends, polyester and linen. However, due to low absorbency and slippery material, DTF inks are not suitable for silk blends.

Best Fabrics for DTF Printing

The most suitable fabrics for DTF printing are the ones with good absorbency. Cotton and cotton blends are considered best for this technique. It retains the design and absorbs the water-based ink for high durability. Due to this, DTF is considered the best print method for custom T-shirts. This works well to create custom items on polyester, blends, and even leather.

Real-Life Durability Tests: DTF vs Other Printing Methods

Compared to DTF printing, prints produced by traditional methods lack durability. Methods like screen printing or Direct-to-garment printing are likely to stretch and break the print. This is because these methods involve sun exposure, long drying time, and complex processes. Washing these items and stretching them can break the designs and prints, as the inks are not cured instantly. After a few washes, these prints lose their natural colour and fade faster than DTF-printed garments.

How to Properly Wash & Care for DTF Printed Clothing

You can follow these wash and care tips for long-lasting apparel that is DTF-printed:

- Avoid using harsh detergent, which can fade the print and cause minor patches.

- It is best to wash your garments inside out for fresh and vibrant prints.

- Avoid ironing your prints and dry the garments in air or low heat settings.

- Cold water is best to prolong these prints.

- You must avoid overloading the washing machine as the friction can damage the prints.

Why Businesses Love DTF for Uniforms & Promotional Gear

DTF printing is a preferred choice for event organisers, companies and sports teams. This can create multiple designs depending on the brand’s needs. Plus, the higher durability ensures longer use of promotional T-shirts, sports jerseys, and corporate uniforms.

Investing in DTF Printing for High-Quality, Long-Lasting Results

Investing in DTF printing can offer higher-quality and durable prints. Unlike other printing methods, you only need a single DTF printer for multiple items. This is cost-effective and can help you produce custom prints, offering profitability and reliability.

Conclusion

DTF printers can help you create lasting prints on multiple surfaces. It is an easy, cost-effective, and environment-friendly printing solution. Businesses can invest in this technology and explore their creative ideas. What are you waiting for? Explore unlimited opportunities to create custom prints using DTF technology today.